Address: No. 69, Jintong Road, Binhai Industrial Park, Xiangshan, Zhejiang

TEL:0086-574-65802978

Mobile:0086-13626819899

E-mail:[email protected]

Gravity casting Casting is the most basic process in th […]

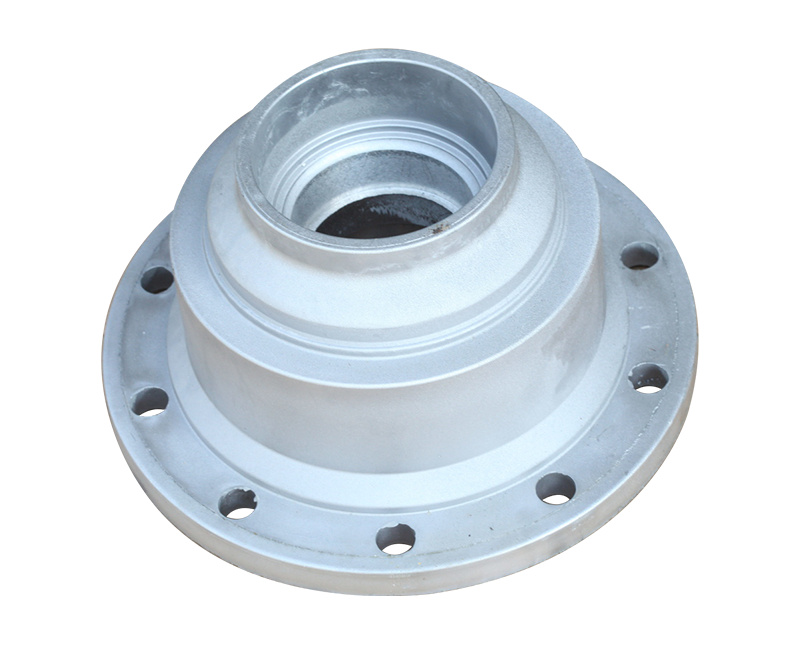

Gravity casting

Casting is the most basic process in the metal processing industry. As early as in prehistoric times, people knew how to use copper to make weapons and other utensils by casting. It heats the metal to a molten state and pours it into the mold to cool it to form. The so-called "gravity casting" is to fill the entire mold with liquid aluminum under the action of gravity. Although this production process is cheap and simple, it is difficult to ensure the consistency inside the rim, it is easy to generate bubbles, and its strength and yield are relatively low. Now this technology has been slowly eliminated.

Low pressure casting

Low-pressure casting is a casting method that uses gas pressure to press liquid metal into the mold and allows the casting to crystallize and solidify under a certain pressure. This method can quickly fill the mold with liquid metal, because the air pressure is not too strong, so it can increase the metal density without being involved in the air. Compared with gravity casting, the internal structure of the low-pressure casting hub is denser and stronger. Low-pressure casting has high production efficiency, high product qualification rate, good mechanical properties of castings, and high utilization rate of aluminum liquid, which is suitable for large-scale supporting production. At present, most of the low-end cast wheels use this process.

Spin casting

Spin casting is a bit like the drawing of ceramics. It is based on gravity casting or low pressure casting, through the rotation of aluminum gimmick itself and the extrusion of the rotary knife, the rim is gradually elongated and thinned. The rim is formed by hot spinning, and there are obvious fiber flow lines on the structure, which greatly improves the overall strength and corrosion resistance of the wheel. Due to the high strength of the material, the light weight of the product, and the small molecular gap of the material, it is a well-received process on the market.

One-piece forging

Forging is a processing method that uses forging machinery to apply pressure to metal blanks to cause plastic deformation to obtain forgings with certain mechanical properties, certain shapes and sizes. After forging, the aluminum embryo has a denser internal structure, and at the same time, the forging process can better heat treat the metal, so that it can obtain better thermal properties. Because the forging process can only process a whole piece of metal embryo and cannot form a special shape, after the aluminum embryo is forged, it also needs to perform a complex cutting and grinding process, and its cost is much higher than the casting process.

Multi-piece forging

One-piece forging requires cutting a lot of extra size, and its processing time and price are relatively high. In order to obtain the mechanical properties equivalent to the one-piece forged wheels, and at the same time reduce the processing time and cost, some automobile wheel brands use multi-piece forging processing methods. Multi-piece forged wheels are divided into two and three pieces. The former is composed of spokes and rims, and the latter is composed of front, rear and spokes. Due to the joint problem, the three-piece wheel hub must be sealed after assembly to ensure air tightness. There are currently two main connection methods for the multi-piece forged hub spoke and rim: one is the special bolt / nut connection; the other is welding. Although the cost of multi-piece forged wheels is lower than that of one-piece forged wheels, it is not as light in weight.

Squeeze casting

The forging process facilitates the processing of parts with complex shapes. The forging process allows the parts to have better mechanical properties, while squeeze casting combines the advantages of the two. In this process, the liquid metal is poured into an open container, and then a high-pressure punch presses the liquid metal into the mold, and fills, shapes, and cools the crystal. This processing method effectively guarantees the compactness inside the hub, and the mechanical properties are close to the one-piece forged hub, and at the same time, there will not be too much residual material to be cut. At present, a considerable part of Japan's wheels have adopted this processing method. Due to the high degree of intelligence, many companies regard squeeze casting as one of the production directions of automobile wheels.